ADDITIONAL INFORMATION

Modular construction is an industrialised process of manufacturing buildings of all types and uses, divided into «modules», usually parallelepipeds, the size of which varies according to the layout and characteristics of the building. In other words, a structure conceived in the form of a meccano, with fully equipped and finished interiors that can be adapted for transport by land or sea, depending on the case.

The building manufactured by the industrialised modular system allows it to be built almost entirely in the factory and then moved and finally assembled on site on the foundations. The need arises for a building with a ground, first and second floor, i.e. three storeys, to house 500 cells in total.

TECHNICAL OFFER

1. Object

On the occasion of the request for financial proposal, we submit our offer no. 2011-245, for Industrialised construction of a building for Penitentiary Centre based on the information provided by Fortenova.

2. Scope

The scope of this offer includes the manufacture and assembly of a building for a Penitentiary Centre with dimensions and distribution as detailed below.

- Will be manufactured in our production facilities.

It is excluded from this offer:

- Foundation works, civil works, horizontal sanitation and urbanisation.

- Connections and connection to urban installations: it will be at the client’s expense to bring these installations to the general switchboard in electrical and communications installations; to the interior of the boiler room in water and gas installations, and the connection of the vertical drainage and rainwater outlets to the horizontal collectors.

- Architectural and installation project.

- Furniture and equipment.

- Licences, permits, taxes, fees, duties and any local taxes, etc.

3. Memory

Description:

The building manufactured by the industrialised modular system allows it to be built almost entirely in the factory and then moved and finally assembled on site on the foundations.

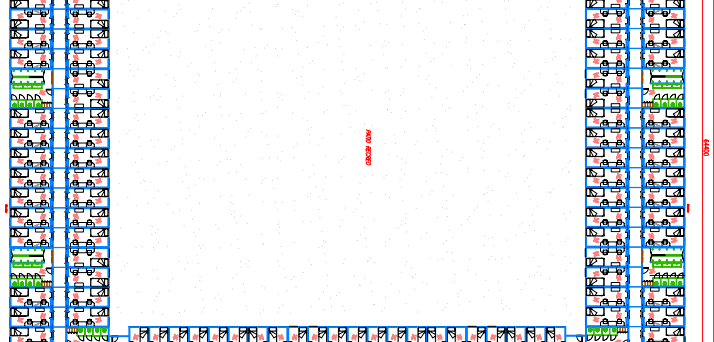

The need arises for a building with a ground, first and second floor, i.e. three storeys, to house 500 cells in total.

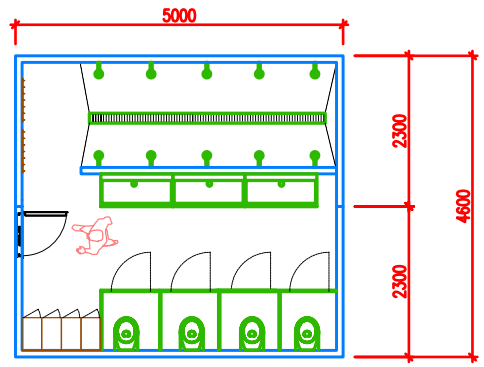

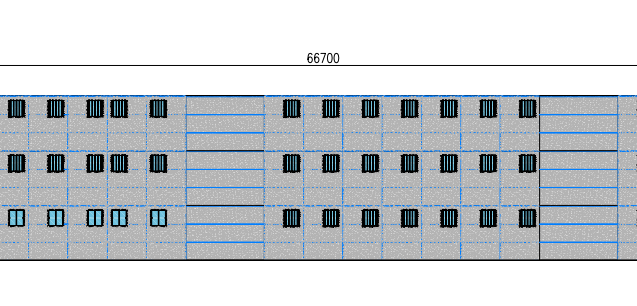

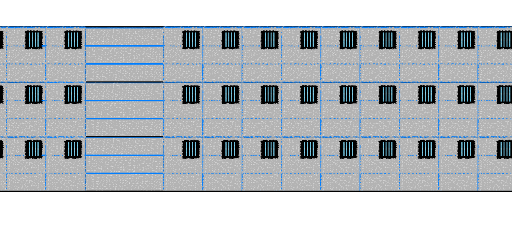

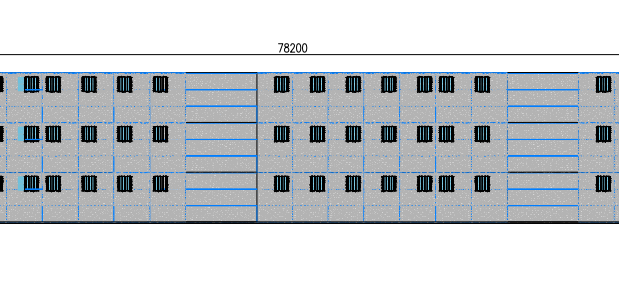

A ground floor plus two storeys building has been planned with modules 11 m long and 2.3 m wide to be transported in a 40′ open top container, making a total of 325 modules to make up the complete building. This distribution and modulation means a built surface area of approximately 8,400 m2 built surface area of approximately 8,400 m2.

The designed cells have a surface area of 11.5 m2 and can accommodate two prisoners with bunk beds.

The toilet modules with shared showers and toilets have a surface area of 23 m2.

The rectangular design of the building allows the cells to be distributed over the three floors with toilet modules on each floor, closing off the building between the modules to leave the central courtyard as a free but controlled and protected area. the central courtyard as a free living area, but controlled and protected.

The building will be brought completely disassembled: floors, walls and ceilings, in order to reduce the cost of sea transport and will be assembled at the destination according to the engineering prepared for this purpose.

4. Logistics and Installation

Logistics:

The modular building is shipped from the factory to its destination, avoiding the deterioration of the materials with suitable protections and, using lifting and transport means adapted to the dimensions and weights of each dimensions and weights of each case.

A special transport fleet is available to transport the modular elements from their modular elements from their manufacturing centre to their final to its final location.

It is understood that access to the site is prepared for the weight and dimensions of these transports and lifting equipment. Unloading at the destination shall be carried out by specialised personnel equipped with the necessary means. For this purpose, an area approximately at the edge of the perimeter of the final location of the building shall be provided for the positioning of lifting equipment.

This surface must be perfectly compacted and have the necessary strength to support the load, but without necessary strength to withstand the load, but without urbanisation during during assembly, so as not to damage possible pavements, kerbs, etc. This unloading work shall be carried out with the aid of an 80 TN crane to guarantee safety on the site.

In addition, a storage area should be provided close to the construction site where the lorries will wait for an entrance. If possible, their circulation on the site should have a non-coincidental entrance and exit, and they should be able to pass next to the lifting equipment, so that the unloading of the modules involves as little displacement as possible. If special permits are necessary for the location of cranes, opening of accesses for transport, adaptation of storage areas, or similar, these shall be requested and shall be paid for by the Owner.

Installation:

With the foundations already laid in situ, the modules will be placed on them, assembling them one by one and then finishing off all the joints, placing the cladding pieces that have been left for this purpose, for example: rows of stoneware, and making the joints of the conduits of the installations, by connectors as in the electrical installation, or by thermowelded or threaded joints as in the plumbing installation.

Finally, the commissioning and testing of the different equipment will be carried out, and the work will then be handed over and then proceed to the handover and reception of the work.